- Aluminum Composite Panel

- PVDF Coating Aluminum Composite Panel

- Nano-PVDF Aluminum Composite Panel

- Polyester Coating Aluminum Composite Panel

- Fire-Proof Aluminum Composite Panel

- Wooden Aluminum Composite Panel

- Wellstone Aluminum Composite Panel

- Brush Finish Aluminum Composite Panel

- Mirror Finish Aluminum Composite Panel

- Aluminum Foil Coil

- PE Painted Aluminum Foil Coil

- PVDF Aluminum Foil Coil

- Slitting Aluminum Foil Coil

- Special Aluminum Foil Coil

Contact Us

Ningbo Rocking Group Co.,Ltd.

Ningbo Rocking Import & Export Co.,Ltd.

Group Add: No.168 Canghai Road, Hi-tech Industry Zone, Ningbo, Zhejiang Province, China.

Head office Add: Office 1203, NO.1 building of powerlong plaza, Hi-tech district, Ningbo, Zhejiang province, China.

TEL: 0086-574-87162491

FAX: 0086-574-87162492

Mobile: 0086-13906618727

Wechat: 0086-13906618727

Whatsapp: 0086-13906618727

Web: www.rockinggroup.com

E-mail: sales@rockinggroup.com

Fire-Proof Aluminum Composite Panel

Description

The panel consists of two sheets of corrosion resistant aluminum

permanently

bonded to fire-resistance core material. The front

aluminum coats PVDF/PE paint

and other finish

design. Because of

its excellent fire-resistance and other features, the panel is used in

some special and important building decoration as exterior

and

interior cladding materials.

It has all advantages of general

aluminum composite

panel and outstanding features of

fire proof

which has overtaken others

in the same

field. It reaches GB8624B1

grade, no flame,

no smog, no noxious gas

no smog, no noxious gas

and its core is

tenacity

and easy to process and installation.

Feature

Excellent fire-resistance feature.

Lightweight, high strength, extreme rigidity and flatness.

Acid-resistance, alkali-resistance.

Outstanding color and gloss retention in a virtually limitless range of hues.

Easily processed and fabricated, quickly installed.

Easily maintenance, simply cleaning.

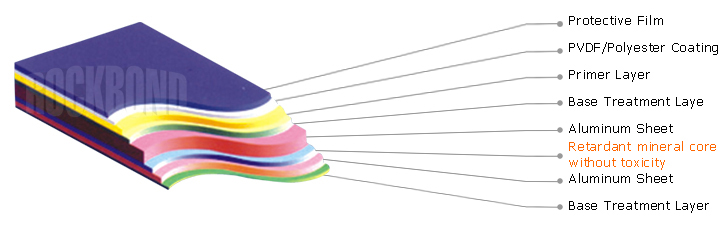

Structure

Fire Resistance Panel Testing:

| Items | Test method | Standard demand | Test result | Conclusion |

| Min. rest length of buring | GB/T 8625-88 | ≥0mm | 330 mm | Qualified |

| Average rest length of buring | GB/T 8625-88 | ≥150 mm | 422 mm | Qualified |

| Average smoke temperature | GB/T 8625-88 | ≤200℃ | 187℃ | Qualified |

| Flame tips height | GB/T 8625-88 | <150 mm | 15 | Qualified |

| Smoke density grade | GB/T 8627-1999 | ≤75 | 11 | Qualified |

| Note: Standard demand is according to difficult combustion (Class B1) materials. | ||||

| Judges according to GB8624-1997, the fire performance of this material rates at class B1. | ||||

| Test Item | Test Condition | Result | Conclusion | Test Standard |

| Height and size | Temperature of 23± 2℃ Relative humidity of 50± 10% |

Flame spread at 1.5min: 60mm | Class 1 | BS476:Part 7:1997 |

| Final flame spread: 60mm | ||||

| Fire safety test | Carried out in accordance with BS476:Part 6:1989 |

Total Fire propagation index: 0.05 | Class 0 | BS476:Part 6:1989 |

| Fire safety test | Temperature of 73± 5F Relative humidity of 50±5% |

Flame spread index: 10 | Class A | ASTM E-84-04 |

| Smoke developed value: 15 |

Why Choose Fireproof Aluminum Composite Panel?

1. Good fire retardancy

Core materials of fireproof Aluminum composite panel adopt nonflammable MG0H, NAOH and PE polymer. Dupont effective coupling agent is also used to enhance the fire retardancy. Our fireproof ACP is easy to process.

2. Weatherability

PVDF coating adopts HYLR5000 and KYNAR500 as the base materials, which enjoys advantages in corrosion resistance, pollution resistance and weatherability. Therefore, our Aluminum composite panel can always keep good appearance, no matter in the hot sun or severe-cold storms. coated Aluminum foil coil

3. High peel strength

We adopt USA advanced Dopont technology and raw materials to enhance the peel strength to the best condition, which has exceeded 50% of national standard. Meanwhile, the flatness of polyester Aluminum composite panel is increased.

4. Impact resistance

Dopont adhesive film, the FULLSUN and JINCHAOYANG paints, Southwest Aluminum alloy are adopted to manufacture Sky rainbow Aluminum composite panel. Due to features of impact resistance, high tenacity and durability, our polyester Aluminum composite panel can keep good shape even in wind-blown-sand’s climate.

5. Even coating and multiple colors

Our company imported forming and coating production lines. Therefore, the whole process is strictly controlled by us. Through forming process and the use of film technology, the coating layer can better adhere to the metal surface. We have multiple colors for your choices.

Standard Colors:

| Silver-flash | Champagne silver |

Sliver grey | |||

| Copper red | Golden | Reddish gold | |||

| Metal grey | Jade silver | Purplish red | |||

| Ivory white | Pure white | Blue |